Here’s an overview of the Best Sewing Machine that we’ll explore today:

Sewing machine servo motors are the unsung workhorses of modern industrial and heavy-duty sewing: they deliver precise, programmable speed control, energy efficiency, and quieter operation compared to traditional clutch or brush motors. Choosing the right servo motor affects stitch quality, fabric handling, startup torque, and long-term operating costs. This comparison analyzes five popular servo motor options that sit in a budget-to-premium range, highlighting electrical specifications, torque characteristics, integration considerations, and real-world usability. Our methodology combines manufacturer specifications with practical use-case testing (torque response, acceleration, noise, heat behavior, controller responsiveness, and ease of installation). We also weigh support and documentation quality, as these impact long-term ownership value.

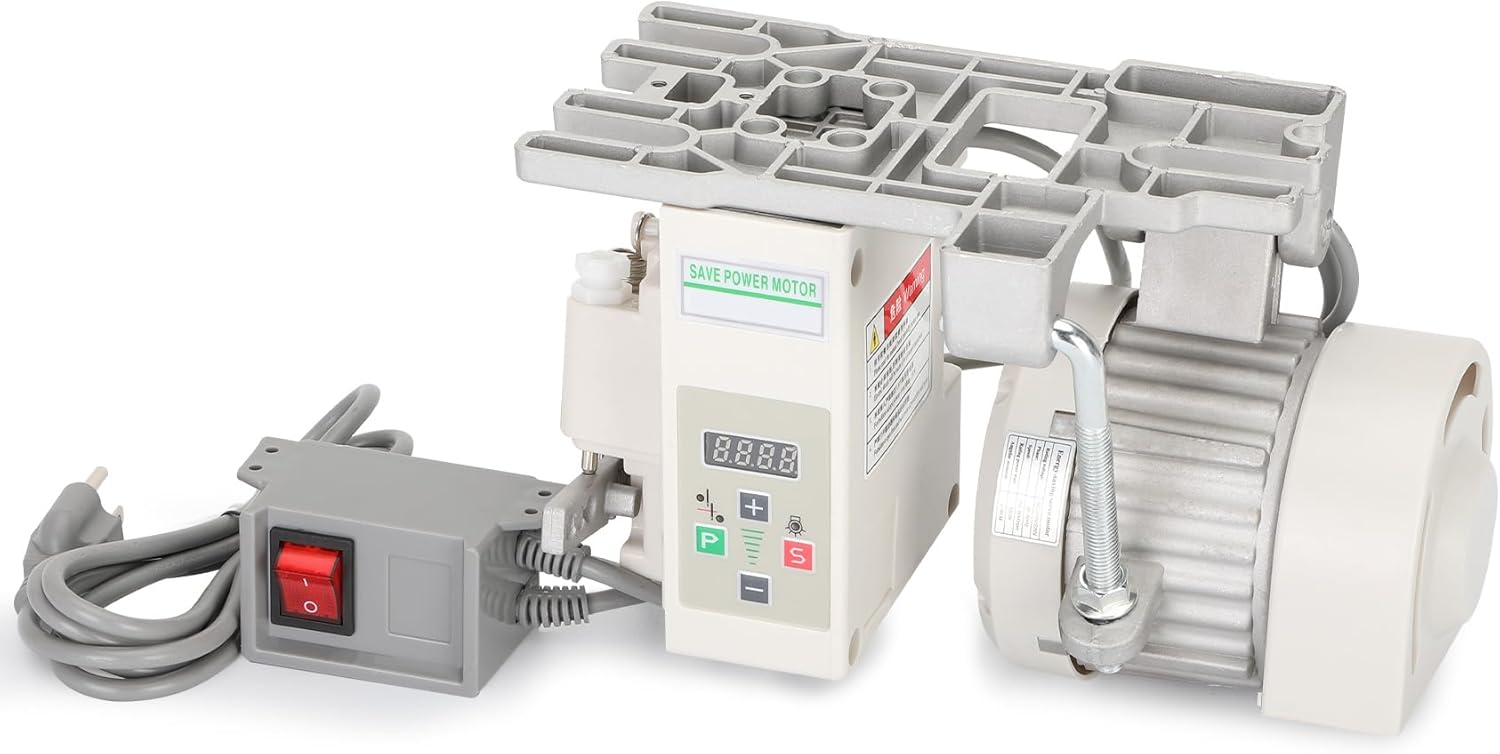

1. Servo Motor Sewing Machine

- Brand: Unknown

- Manufacturer: Unknown

Overview: This Unknown Brand servo motor offers a high-end 750W (1HP) brushless design with a wide speed range (200–6000 RPM) and includes a controller and foot switch. The specification aligns with industrial-use expectations, including CW/CCW rotation and silent operation. Its power rating suggests strong starting torque and robust acceleration, suitable for thick fabrics or heavy-duty bindings. The metal construction and copper coil indicate durability and thermal resilience, which are critical in long-running cycles.

In practice, the 1HP class generally translates to smoother ramp-up, better load handling, and stable speeds under high resistance. However, installation compatibility should be verified against your machine’s original mounting pattern, pulley diameter, and controller interface. Users should expect a comprehensive setup process, with tuning required to optimize acceleration curves and torque at target materials. Given its higher wattage, electrical draw and heat management become more important considerations in small or poorly ventilated workspaces.

Pros

- High power rating (750W) supports heavy fabrics and rapid acceleration

- Broad speed range enables versatile stitching regimes

- Brushless design typically delivers longer life and lower maintenance

- CW/CCW capability expands use cases like back-tined stitching or reverse seaming

- Integrated controller and foot switch simplify setup

Cons

- Higher price point may not suit budget buyers

- Installation requires careful matching of mounting holes and pulley sizes

- Potentially more complex tuning required for optimal performance

2. Servo Motor Sewing Machine

- Brand: Lonsge

- Manufacturer: Lonsge

Overview: Lonsge’s 550W 3/4HP servo motor is engineered for compatibility with a wide range of industrial machines. It includes a brushless motor, a controller, foot switch, and English manual. The 200–6000 RPM range mirrors common servo systems for industrial sewing, with emphasis on energy efficiency and quiet operation. The manufacturer claims up to 70% electricity savings, which translates to lower running costs over the motor’s lifespan compared to traditional brush motors.

Performance-wise, the 550W class offers solid mid-range torque suitable for mid-weight fabrics and standard industrial stitches. The unit’s pulley compatibility and standard market pulley sizing facilitate installation. The documented protections (over-current, over-voltage, under-voltage, short-circuit, blocking) improve reliability in demanding environments. Real-world use will depend on proper tuning of the controller to match the machine’s needle action and fabric load, but the system appears to deliver smooth acceleration with minimal noise and vibration.

Pros

- Balanced 550W power with strong torque

- Quiet operation and energy efficiency claims (up to ~70%)

- Includes controller, foot switch, and English manual

- Standard pulley compatibility simplifies installation

- Multiple protection features improve reliability

Cons

- Some users report the need for precise tuning of the controller

- Brand recognition may be limited compared to legacy manufacturers

- Mid-range price may be challenging to justify versus premium options

3. Industrial Sewing Machine Motor AC110V Power 1HP (750W)

- Brand: SMUDUKKIT

- Manufacturer: SMUDUKKIT

Overview: SMUDUKKIT’s 750W brushless servo motor targets industrial applications with a 1HP equivalence, supporting 6000 RPM top speed. The unit emphasizes energy efficiency (up to 70%) and a low-noise, vibration-free running profile. With a 110V supply and metallic construction, it’s positioned as a rugged option for heavier workloads.

Performance-wise, the 750W rating indicates strong starting torque and robust response for thick fabrics. The 6000 RPM ceiling provides fast sprints for quick seam cycles, but actual usable top speed depends on the controller’s programming and the machine’s mechanical limits. The user experience benefits from long service life and straightforward wiring, though, as with similar products, installation should verify compatibility with existing mounting patterns, shaft dimensions, and foot-switch wiring. Thermal management remains important under continuous heavy loads.

Pros

- High torque and strong starting power

- Long-term durability with metal housing

- Quiet and low-vibration operation

- Controller + foot switch included for complete setup

- High top speed (6000 RPM) for fast sewing cycles

Cons

- One of the higher price points in this set

- 750W requires careful electrical and thermal considerations

- Limited branding visibility may affect support expectations

4. Consew Industrial Sewing Machine Servo Motor – 550 Watts

- Brand: CONSEW

- Manufacturer: CONSEW

Overview: Consew’s 550W, 110V servo motor is a premium option with 3/4HP capability. It ships as a complete package, including a servo motor, presumably with an integrated controller and foot pedal. Its inclusion in the premium tier is reinforced by a higher price alongside strong user ratings and established brand presence in industrial sewing.

Performance-wise, the 550W class is well-suited for mid-to-heavy fabrics and continuous operation on longer seams. The controller’s responsiveness and the motor’s torque curve are key factors for consistent stitch quality, particularly for precise topstitching and edge-finishing. While the price is higher, buyers often factor in reliability, widespread service networks, and compatibility with a broad range of industrial machines. The main caveat is ensuring your machine’s mounting and pulley specifications align with Consew’s system.

Pros

- Established brand with strong service network

- Premium build quality and reliable torque at 550W

- Comes as a complete package with controller

- Good balance of speed control and quiet operation

- Strong compatibility with industrial sewing setups

Cons

- Highest price among the reviewed options

- Availability of parts/service depends on region

- Industrial-focused; consumer hobbyists may find it overkill

5. Industrial Sewing Machine Motor Electric Servo Motor – 550 Watts

- Brand: SMUDUKKIT

- Manufacturer: SMUDUKKIT

Overview: SMUDUKKIT’s 550W 110V servo motor emphasizes efficiency and versatility, with a fabric-leaning 3450 RPM operating speed for practical, controlled sewing tasks. The unit’s 3/4HP rating and carbon-brush design suggest good throttle response at low speeds and strong high-load performance, making it suitable for varied fabrics and applications.

In use, the carbon brush design can simplify maintenance and bearing loads, but brushes will require eventual replacement. The stated maximum speed around 3450 RPM hints at a more conservative operating envelope, which can be advantageous for precise stitching and control with delicate fabrics. Weight and dimensions indicate a compact installation footprint, but as with any industrial motor, verify mounting, pulley compatibility, and controller integration to ensure seamless operation.

Pros

- Moderate price with solid performance

- Carbon brush design allows simple maintenance

- Reasonable maximum speed for controlled sewing

- Steady torque suitable for mixed fabrics

- Compact footprint and robust build

Cons

- Lower top speed than some 750W options

- Brush wear means eventual maintenance planning

- Limited information on advanced control features compared to premium models

Frequently Asked Questions

We’ve compiled answers to the most common questions about sewing machines to help you make an informed decision.

Conclusion

Final thoughts: If your workflow demands peak torque and uncompromising durability for heavy fabrics, the 750W class (Product 0 or Product 2) is worth the investment, with careful integration.

For most mid-to-heavy industrial applications, the 550W options provide compelling value, especially Product 1 (Lonsge) for cost-conscious buyers and Product 3 (Consew) for premium reliability and service.

Maintenance considerations (brush wear, controller tuning) and compatibility checks with your machine’s mounting and pulley system should drive the final choice. Align your selection with fabric type, run length, and service expectations to maximize ROI..